|

|

| The

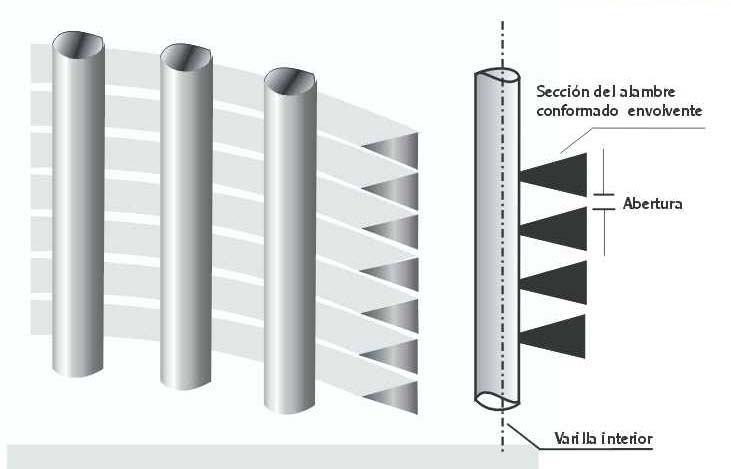

wedgewire products are manufactured by rolling a V-Shape wire

around an internal framework of longitudinal bars. The external

V-Shape wire can have either a sharp end, in what is known as

Vee-Wire Sharp, or it can have a round end in what is known

as a Vee-Wire Wear. The wire and the bars are made of carbon

steel, carbon steel galvanized, stainless steel, copper or any

alloy and they are joint using resistance welding.

|

|

|

| The

continuous slot wedgewire products are used in a wide variety

of industries, such as, construction of water wells, drainage

wells, breweries-malting industries, water and wastewater, treatment,

as intakes for dams, rivers and lakes, different mining process

(clarification, dewatering, and selection process), food industry

and in many other processes and industries. Even though it wedgewire

products have multiple uses, this product was originally developed

in the United States in order to solve the problems associated

with water wells built in fine and very fine uniform sands formations.

|

|

|

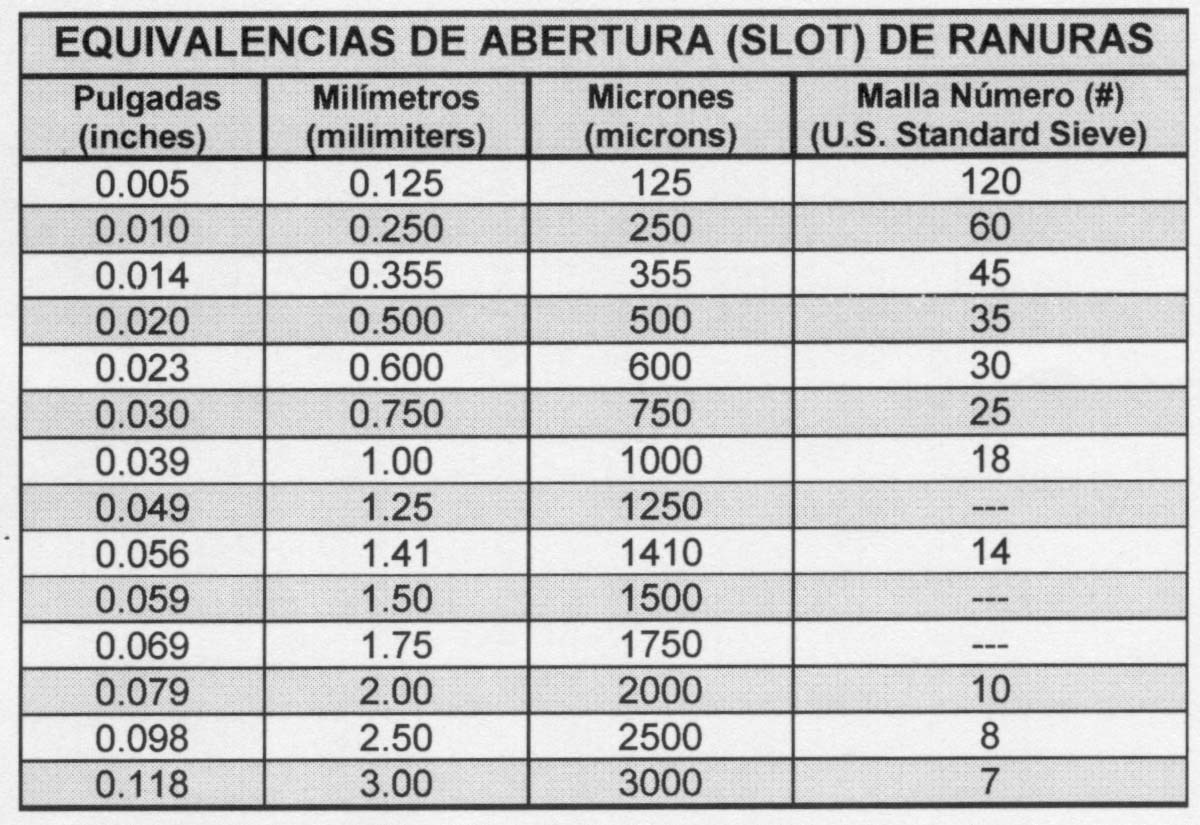

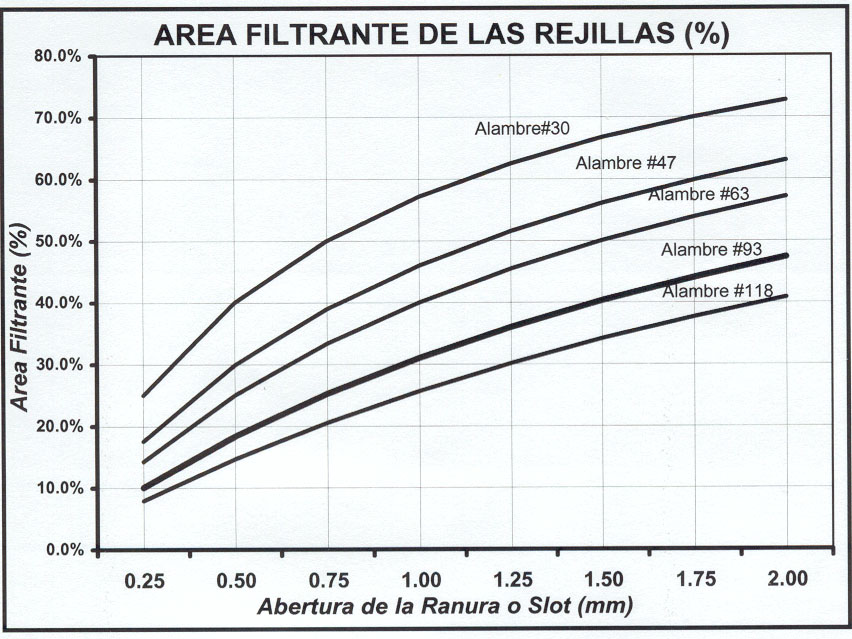

Depending

on the type of wire used and the slot opening, the open

area of a wedgewire screen can vary between 10% and 70%

of the total area (see graph). The average opening area

of a water well screen varies from 35% to 45% compared

with 5% to 15% on average of a other scrrens (e.g. perforated

or bridge screen). In the case of support grids, the filtering

area can be up to a 70% of total area, depending on the

material used and the slot.

The continuos slot water screen has several advantages

compared to other screens such as bridge slot screen or

perforated screen A larger opening (filtering) area of

a wedgewire screen leads to superior performance of a

water well compared against the installation of other

types of screens. Moreover a wedgewire filter for water

well are self-cleaning (go-no go), thus, prevents losses

due to friction as well as losses associated with pumping

sand. Also, a continuous slot wedgewire water well screen

eliminate the problems associated with fine sands, thus,

increasing the life of the pumping equipment.

|

|

|

|

Benefits

of continuos slot wedgewire screens are many, among some of

those are:

- Continuos

slot screen offers a larger opening (filtering) area, which

lead to a larger production of the water well. This fact,

implies a reduction of the long-term average cost of the

system.

- A

greater opening area (filtering area) reduces the pressure

in the systems and head loss, and therefore reduces energy

consumption.

- Minimal

water frictional head loss which lead to an increase in

the efficiency of the water well and/or filtering systems.

- Elimination

(reduction) of the problems associated with pumping of fine

sands in water wells. Longer useful life of the system,

which reduces the cost of capital and operational cost in

the long run.

- In

the case of water screens, these are self-cleaning, which

leads to a reduction of the maintenance cost and longer

life of pumping equipment.

- Stainless

steel or galvanized wedgewire screens offer a greater resistance

to accelerated corrosion.

- Minimum

failure risk in the construction process especially in wells

built in thin aquifers.

- Failure

risk reduction of the filtering system.

- Products

design can be esaily adapted to any specific project at

a minimun cost

The priority of our engineering team is to technically support

all its clients in any type of work or needs with the goal

designing the adequate product for each project. For technical

support, questions or prices please email us at: info@filper.com.

|

Filper © Copyright 2015 - All rights reserved - Editado por Wildesk

|

|

|